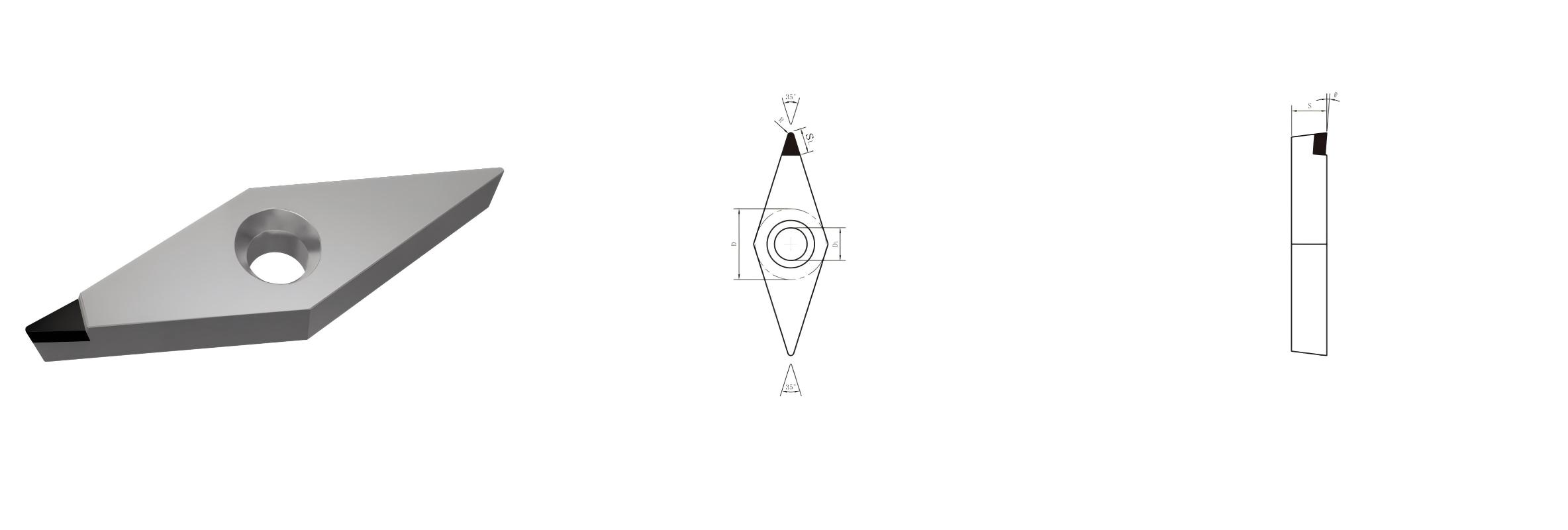

| Type | Dimensions(mm) | ||||

| D | S | R | D1 | SL | |

| VCGT110302 | 6.35 | 3.18 | 0.2 | 2.8 | 3.0 |

| VCGT110304 | 6.35 | 3.18 | 0.4 | 2.8 | 3.0 |

| VCGT160404 | 9.525 | 4.76 | 0.4 | 4.4 | 3.0 |

| VCGT160408 | 9.525 | 4.76 | 0.8 | 4.4 | 3.0 |

| VCGT160412 | 9.525 | 4.76 | 1.2 | 4.4 | 3.0 |

| Grade | Granularity (μm) | Characteristics | Application |

| MPD85 | Submicron | Ultra-fine grain structure,strong edge sharpness and edge durability. | Ultra high precision machining is applicable to the milling of aluminum alloy with extremely high requirements for blade breakage,mainly used for the machining of composite materials |

| MPD02 | 2μm | It has good electric machinability, toughness and surface finish of machined workpiece. | It is mainly used for processing of forming milling cutter and thread cutting cutter,as well as wear-resistant parts, woodworking and silicon aluminum alloy processing. |

| MPD05 | 5μm | Excellent electric spark and machinability,good toughness, wear resistance and edge quality | It is suitable for high finish surface finishing,mainly used for processing organic glass,silicon aluminum alloy,metal mobile phone shell contour,etc. |

| MPD10 | 10μm | Universal PCD Grade,good toughness and high abrasion resistance | Suit for single tool for rough machining,especially for wood molding,medium and low silicon aluminum alloy parts (such as piston). |

| MPD25 | 25μm | High wear resistance and edge quality | It is suitable for processing high silicon aluminum alloy,metal matrix composite (MMC),hard alloy,ceramics,graphite and other brittle hard materials. |

| MPD302 | 2-30μm | Mixed 2μm and 25μm,good wear resistance and edge quality and edges strength | Applications include metal matrix composites(MMC),high silicon aluminum alloys,and bimetallic applications. |

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.